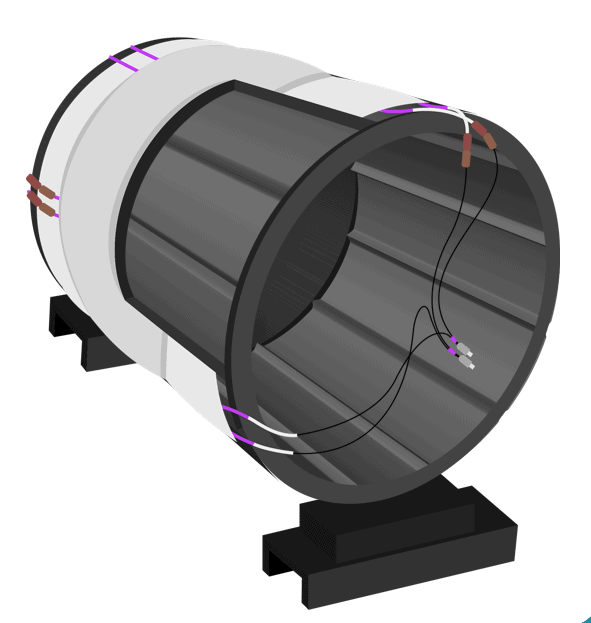

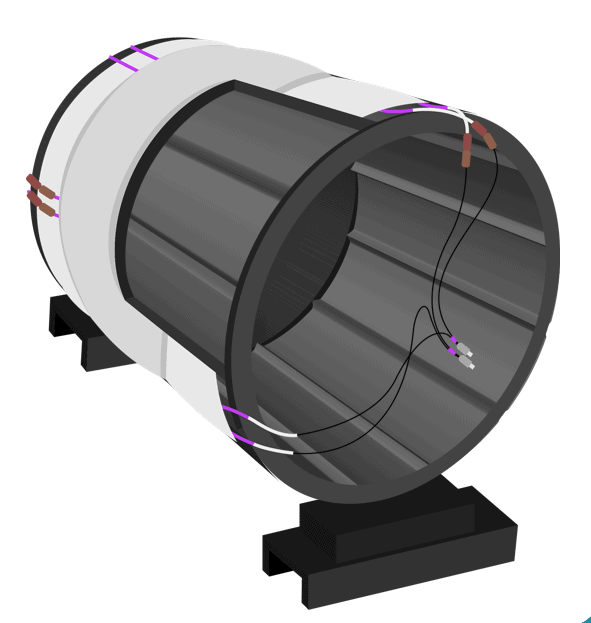

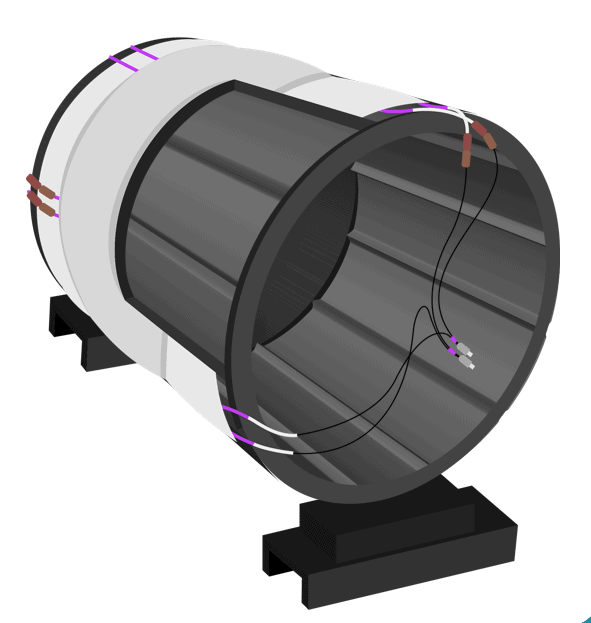

Axi-Therm Blended Heating & Cooling is a new Heat Treatment method utilizing the use of 1, 2 or all 3 heating methods simultaneously to help maximize temperature dissipation into the heated area and a cooling method once the metal design criteria have been met.

Reducing costs on the front end and improving your time back to production on the back end.

The properties of metals are impacted by the application of heat. Heat in its various methods and application are used to ensure the chemical makeup and grain structures of the metal change during the heating process to meet the design criteria the metal is intended to be used for.

It is therefore of paramount importance to adhere to the correct heating, cooling, and hold times throughout the heating process.

The primary metallurgical values we are typically trying to achieve in field heat treatment are - strength, ductility, malleability, and hardness. A reader's digest description of each value are listed below:

STRENGTH - Strength is the ability of a material to resist deformation under a pressurized load.

DUCTILITY - Ductility is the ability of a material to deform easily upon the application of a tensile force.

MALLEABILITY - Where ductility is the ability of a material to deform easily upon the application of a tensile force, malleability makes the metal easy to roll or machine without compromising its structure.

HARDNESS - Enables the metal to resist deformation, penetration, indentation, and scratching and is often checked for before and after heat treatment to ensure desired results have been met.